We are obsessive about preserving the naturalness of Stevia while we extract it from the Stevia leaf. To this effect, we use a proprietary process for Stevia Extraction that is 100% Organically certifiable and does not use any chemicals. Unlike other manufacturers who use resin and ion exchange based processing methods, our process:

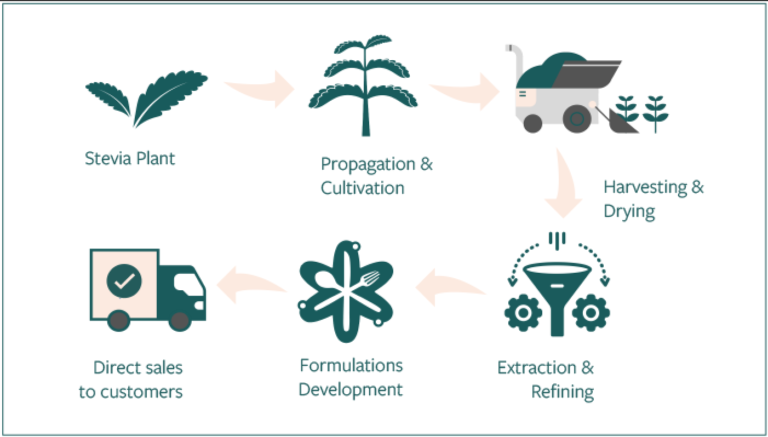

Using our novel process, we efficiently convert the dried stevia leaves into creamish white powder that we call the crude extract. The crude contains a whole range of sweet compounds (upto 38 different steviol glycosides) apart from various other natural compounds present in the Stevia leaf (for instance: diterpenes, flavonoids, saponins etc). These extra compounds are essentially impurities (as they have their own distinctive flavor and taste profile). Within the 38 different glycosides too, some molecules are better tasting than the others, and this crude is hence further ‘refined’ to enrich the composition of the better tasting molecules while neutralising/filtering the impurities and not so great tasting steviol glycosides. Goes without saying, this refining process used is also Organic.

The refining process makes it possible to deliver standardised grades of high purity Stevia extracts that you can use in your food & product recipes. This high degree of standardisation is key to ensuring a consistent taste profile of commercial products. The refined extracts comply with international purity standards (US FDA, JECFA, EFSA etc) and are 95% purity or higher. The purity of these refined extracts is measured by TSG (Total Steviol Glycoside) content and the different grades available are typically labeled by the minimum amount of Reb A in them.

While a) above is dependent upon the plant variety, b) and c) have a dependency on the type of processing method adopted for manufacturing Stevia extracts. At Arboreal, we have mastered the science behind optimising this last 5%. And in many applications, that 5% makes all the difference between Bitter Stevia and Better Stevia.