In the complex dance of supply chains, the role of intermediaries has become the subject of intense debate and discussion. Whether domestic or international distribution companies, intermediaries often prove to be essential links in the supply chain. However, their middling position, lacking direct production or tangible benefits, has raised questions about the true value they bring. In this article, we will explore how the involvement of multiple intermediaries can affect the supply chain and why this is an area of concern.

The Middleman Conundrum

Intermediaries, also known as intermediaries, occupy a unique position in the supply chain. They act as a bridge facilitating the distribution and transaction of goods and services from manufacturers to consumers. While this role may sometimes seem necessary, it is essential to consider the impact of using multiple intermediaries.

- Dependency and Loss of Control: One of the main concerns with having multiple intermediaries is the potential loss of control over the supply chain. When goods pass through many different hands, the company in control may have difficulty monitoring and ensuring that the product reaches the consumer in the desired condition. Dependence on intermediaries can lead to a lack of transparency and accountability.

- Financial Drain: From a financial standpoint, using an intermediary can be costly. At each stage of the supply chain, including warehousing, insurance, transportation, and advertising, each intermediary’s profit margin is considered. Although these costs may seem small, they add up as the product moves through the chain. Ultimately, these costs are borne by consumers, which can impact sales, especially in today’s highly competitive market.

- Price Amplification: Every time a product is transferred throughout the supply chain, its price tends to increase. This is due to the addition of profit margin for each intermediary involved. The result is that consumers pay more for the final product, which can significantly impact their choices, especially in markets with high price sensitivity.

- Inefficiency and Delays: The presence of many intermediaries can cause inefficiencies and delays in the supply chain. Each intermediary may have its processes, protocols, and deadlines, which can slow down the movement of goods. This can be especially problematic in industries where on-time delivery is essential.

- Competition and Market Dynamics: In today’s business environment, competition is fierce. Companies are optimizing their supply chains to reduce costs and gain a competitive advantage. The presence of multiple intermediaries can introduce complexity and potentially hinder a company’s ability to adapt to rapidly changing market dynamics.

The Domino Effect

The spillover effects of multiple intermediaries in the supply chain can be significant. It starts with the manufacturer, who may have to factor in higher costs due to the involvement of middlemen. This, in turn, impacts the price at which the manufacturer sells its product to the next intermediary. As products move through the chain, the cumulative impact of these additional costs becomes increasingly apparent. Ultimately, the consumer feels the financial burden, which can influence their purchasing decisions. Additionally, the presence of intermediaries can make it difficult for companies to respond quickly to changes in demand or changes in consumer preferences. This lack of flexibility can lead to inventory problems, excessive costs, and a reduced ability to remain competitive in the market.

Streamlining the Supply Chain

Companies are increasingly looking to streamline their operations to minimize the negative impact of multiple intermediaries in the supply chain. Here are some of the strategies they employ:

- Direct-to-Consumer (DTC) Models: Many companies are adopting the DTC model, which allows them to sell directly to consumers, bypassing the middleman. This approach can improve control, reduce costs, and improve the overall customer experience.

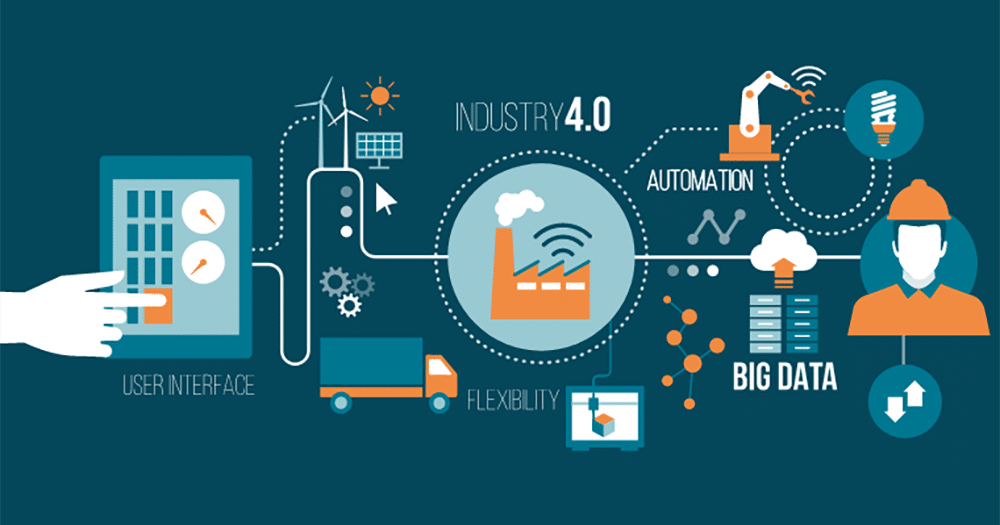

- Technology Integration: Leveraging technology, such as blockchain and supply chain management software, can provide greater visibility and transparency throughout the supply chain. This helps reduce inefficiencies and increase accountability.

- Vertical Integration: Some companies choose vertical integration to acquire or establish their own intermediaries to better control different stages of the supply chain.

- Collaborative Relationships: Establishing close working relationships with trusted intermediaries can help alleviate some of the challenges associated with multiple intermediaries. Clear communication and common goals can streamline operations.

Having multiple intermediaries in the supply chain can cause complexity, inefficiency, and increased costs. While intermediaries play an important role in facilitating the distribution and trading of goods and services, their involvement must be carefully managed to minimize negative impacts on the supply chain. Agile, tech-savvy, consumer-focused businesses are better positioned to address the challenges posed by intermediaries and deliver value to manufacturers and consumers. By addressing these concerns, businesses can work to create simpler, more efficient supply chains that meet the demands of today’s dynamic marketplace.